Knife Repair

Someone local came across this blog and asked me to repair an old knife he had. Pictured above is the old handle next to the replacement. Seems the aluminum rivets in german knife handles act as anodes, causing them to corrode quickly and fall apart. I machined the replacement rivets of stainless, and the handle of lignum vitae.

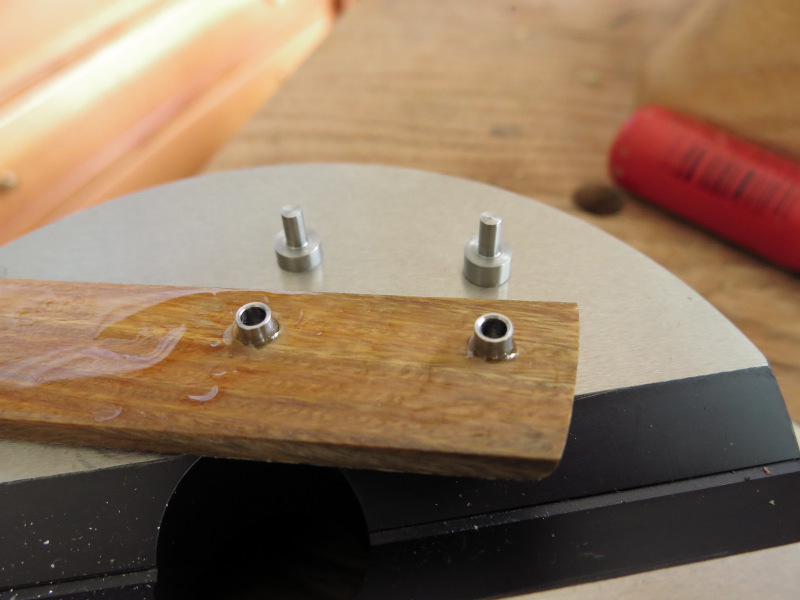

It’s a pain to counterbore knife scales without a piloted counterbore, so I hacked one out on the bench grinder:

Having made a couple more palms since the last post, I wanted to put one to the test. I sewed a ditty bag of #4 cotton duck, stiff and strong. The bag was all sorts of experiments with materials and technique so it’s not the tidiest.

The latest palms have silver-brazed eyes and brass eyelets.

Above is also a knife sheath I made of wood and aluminum. The knife is a cleaned-up McMaster No. 3948A11. Also made some other sailmaker’s tools-

The most important tool I made is not especially photogenic:

It’s thread wax- I have used beeswax, ‘composition wax’ from sailrite, stick wax sawing lubricant, paraffin, lanolin, and others. The stick wax sawing lubricant works alright, but the thread wax pictured above is perfection. I melted beeswax and stirred in pine tar till it seemed dark enough, maybe 1:1. I made a few different pieces with varying ratios, more pine tar makes for softer wax that ‘wets’ the fibers more readily. Too much and it is messy. The combo also makes it easier to grip the needle with your fingers. This wax (the tarrier stuff) made the eye splices on the ditty bag possible–the nylon rope I had explodes like a cattail into a million tiny spider-web-thin strands when cut.

One catch: it does smell like a stinky campfire.